WELCOME TO Ayyappa Instalation works .

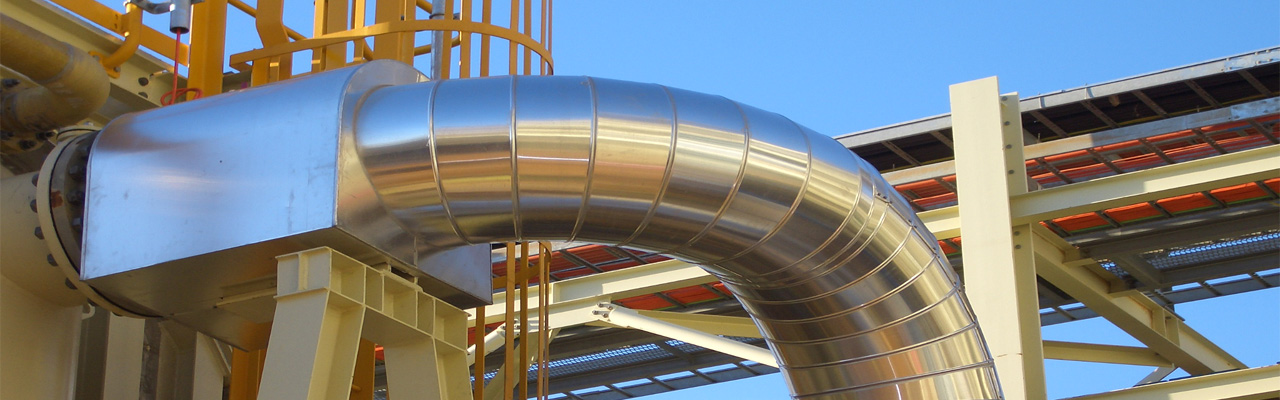

Ayyappa Instalation works is specialist in Hot and Cold Insulation, Acid Proof Tiles Lining work, All type of painting work, Fabrication work and AHU DUCTING works and Civil work.

REGISTRATION DETAIL

| 1 | PAN NO. | ABOPO4201A |

| 2 | GST | 24ABOPC4201A2ZJ |

| 3 | P.F reg. No | SRVAP1635423000 |

| 4 | ESIC NO. | 39000551680000606 |

| 5 | LABOUR LICENCE NO. | BRD/16395 |

| 6 | P.T Employee Reg. no | PR2508001056 |

| 7 | P.T Employeer Reg. no | PE2508001049 |

| 8 | TAN no. | SRTR08364G |

| 9 | Licence No. | l.c.6/CLRA/LICENCE/CLRA/VLS/2018/CIL/599 |

Discription

Insulation

Insulations are defined as those materials or combinations of materials which retard the flow of heat energy by performing one or more of the following functions:

- Conserve energy by reducing heat loss or gain.

- Control surface temperatures for personnel protection and comfort.

- Facilitate temperature control of process.

- Prevent vapour flow and water condensation on cold surfaces.

- Increase operating efficiency of heating/ventilating/cooling, plumbing, steam, process and power systems found in commercial and industrial installations.

- Prevent or reduce damage to equipment from exposure to fire or corrosive atmospheres.

- Assist mechanical systems in meeting criteria in food and cosmetic plants.

- Reduce emissions of pollutants to the atmosphere.

Temperature Ranges

The temperature range, within which the term "thermal insulation" will apply, is from -75°C to 815°C. All applications below -75°C are termed "cryogenic", and those above 815°C are termed "refractory".

Thermal insulation is further divided into three general application temperature ranges as follows:

- (1). 5°C through 0°C - i.e. Cold or chilled water.

- (2). 0°C through -40°C - i.e. Refrigeration or glycol.

- (3). -40°C through -75°C - i.e. Refrigeration or brine.

- (4). -75°C through -275°C (absolute zero) - i.e. Cryogenic.

- (1). 16°C through 100°C - i.e. Hot water and steam condensate.

- (2). 100°C through 315°C - i.e. Steam, high temperature hot water.

- (1). 315°C through 815°C - i.e. Turbines, breechings, stacks, exhausts, incinerators.

Insulation Types

Insulation materials are generally divided into three main types:

composed of small diameter fibres which finely divide the air space. The fibres may be perpendicular or parallel to the surface being insulated, and they may or may not be bonded together. Silica, rock wool, slag wool and alumina silica fibres are used. The most widely used insulations of this type are glass fibre and mineral wool. Glass fibre and mineral wool products usually have their fibres bonded together with organic binders that supply the limited structural integrity of the products.

composed of small individual cells separated from each other. The cellular material may be glass or foamed plastic such as cellular glass, phenolic foam or nitrile rubber.

composed of small nodules which may contain voids or hollow spaces. It is not considered a true cellular material since gas can be transferred between the individual spaces. This type may be produced as a loose or pourable material, or combined with a binder and fibres or undergo a chemical reaction to make a rigid insulation. Examples of these insulations are calcium silicate and vermiculite.

Insulating Materials-Hot and Cold Applications

The following is a general inventory of the characteristics and properties of major insulation materials used in commercial and industrial installations.

Glass: Available as flexible blanket, rigid board, pipe covering and other premolded shapes. Service temperature range is up to 535°C.

Rock and Slag: Rock and slag fibres are bonded together with a heat resistant binder to produce mineral fibre or wool. Upper temperature limit can reach 1035°C.

Available in board and block form capable of being fabricated into pipe covering and various shapes. Service temperature range is -260C to 200°C and to 650°C in composite systems. Good structural strength, poor impact resistance. Material is non-combustible, non-absorptive and resistant to many chemicals.

Calcium Silicate is a granular insulation made of lime and silica, reinforced with organic and inorganic fibres and moulded into rigid forms. Service temperature range covered is 35°C to 815°C. Flexural and compressive strength is good. Calcium silicate is water absorbent. However, it can be dried out without deterioration. The material is non-combustible and used primarily on hot piping and surfaces. Finishing material is applied on site.

Perlite is made from an inert siliceous volcanic rock combined with water. The rock is expanded by heating to above 535°C causing the water to vaporize and the rock volume to expand. This creates a cellular structure of minute air cells surrounded by vitrified product. Added binders resist moisture penetration and inorganic fibres reinforce the structure. The material has low shrinkage and high resistance to substrate corrosion. Perlite is non-combustible and operates in the intermediate and high temperature ranges. The product is available in rigid pre-formed shapes and blocks.

Foamed resins combined with elastomers produce a flexible cellular material. Available in pre-formed shapes and sheets, elastomeric insulations possess good cutting characteristics and low water and vapour permeability. The upper temperature limit is at 105°C. Elastomeric insulation is cost efficient for low temperature applications with no cladding necessary. Resiliency is high. Consideration should be made for fire retardancy of the material.

Insulations produced from foaming plastic resins create predominately closed cellular rigid materials. "K" values or lambda values decline after initial use as the gas trapped within the cellular structure is eventually replaced by air. Check manufacturers' data. Foamed plastics are light weight with excellent cutting characteristics. The chemical content varies with each manufacturer. Available in pre-formed shapes and boards, foamed plastics are generally used in the lower intermediate temperature range. Consideration should be made for fire retardancy of the material.

Refractory fibre insulations are mineral or ceramic fibres, including alumina and silica, bonded with extremely high temperature inorganic binders, the mechanical interlocking of fibres eliminates the need for any binder. The material is manufactured in blanket or rigid form. Thermal shock resistance is high. Temperature limits reach 1750 °C. The material is non-combustible.

Rigid closed cell foamed insulation manufactured from phenolic resin.

Insulating and finishing cements are a mixture of various insulating fibres and binders with water and cement, to form a soft plastic mass for application on irregular surfaces. Insulation values are moderate. Cements may be applied to high temperature surfaces. Finishing cements or one-coat cements are used in the lower intermediate range and as a finish to other insulation applications. Check each manufacturer for shrinkage and adhesion properties.

WE PROVIDE

Building insulation refers broadly to any object in a building used as insulation for any purpose. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation (e.g. for vibrations caused by industrial applications). Often an insulation material will be chosen for its ability to perform several of these functions at once

Installed on piping and mechanical systems to achieve one or more of the following; energy savings, personnel protection, process control, condensation control, noise reduction and reduction of greenhouse gas emissions. Mechanical systems include piping, boilers, HVAC systems, and ducts. Mechanical insulation is commonly installed in industrial and commercial facilities.

Our Products

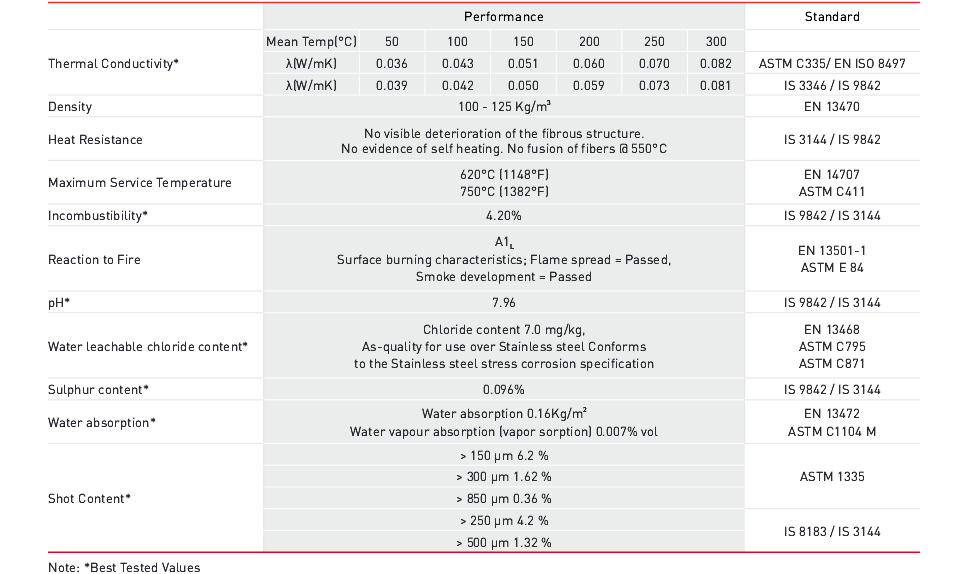

ProRox PS 960

ProRox PS 960 is a pre-formed stone wool pipe section. The sections are supplied split and hinged for easy snap- on assembly and are suitable for the thermal and acoustic insulation of industrial pipe work.

Read More

ProRox PS 970

The sections are supplied split and hinged for easy snap-on assembly and are especially suitable for the thermal and acoustic insulation of industrial pipe work which is exposed to high temperatures and light mechanical loads (e.g. vibrations).

Read More.jpg)

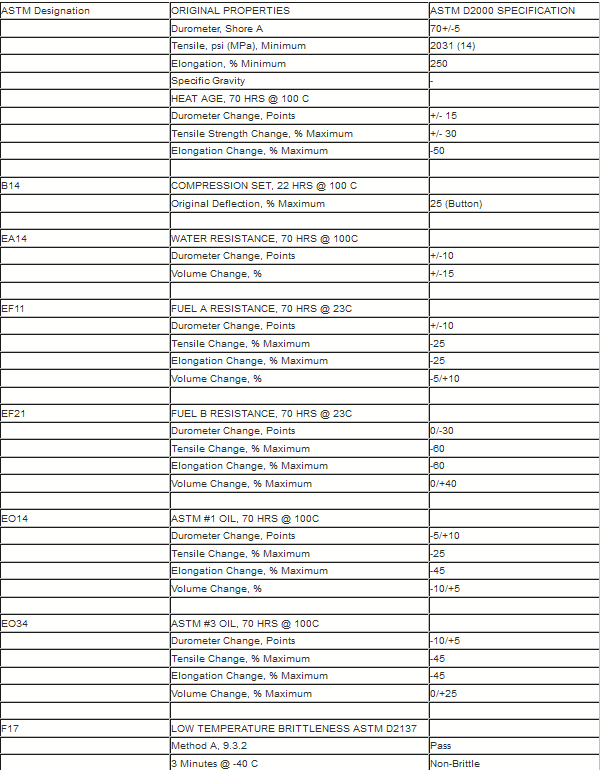

Nitrile rubber (NBR)

In the production of NBR, acrylonitrile (CH2=CHCN) and butadiene (CH2=CH-CH=CH2) are emulsified in water and then polymerized (their single-unit molecules linked into large, multiple-unit molecules) through the action of free-radical initiators.

Read More

ProRox PS 970 In

The sections are supplied split and hinged for easy snap-on assembly, and are especially suitable for the thermal and acoustic insulation of industrial pipe work

Read More

ProRox WM 950

The wired mat is suitable for thermal acoustic insulation of industrial applications reaching high temperatures

Read More

ProRox WM 960

The wired mat is especially suitable for industrial applications such as high-pressure steam pipes, reactors, furnaces, etc.

Read More

ProRox WM 970

The wired mat is especially suitable for industrial applications such as high-pressure steam pipes, reactors, furnaces, etc..

Read More

ProRox WM 970 In

The wired mat is especially suitable for industrial applications such as high-pressure steam pipes, reactors, furnaces, ets.

Read More

ProRox WM 980 In

The wired mat is especially suitable for industrial applications such as high-pressure steam pipes, reactors, furnaces, ets.

Read More

ProRox SL 950

ProRox SL 950 (ROCKWOOL HT 600) is especially developed for the thermal and acoustic insulation of high temperature columns and vessels.

Read More

Thermocol Insulation Sheets

We have in store for our clients an effective range of Thermocol Insulation Sheets for our clients in the form of “nd” & “tf” quality.

Read More

ProRox SL 960

ProRox SL 960 (ROCKWOOL 233) is specially developed for the thermal and acoustic insulation of technical equipment such as reservoirs, ovens, boilers

Read More

ProRox SL 970 In

It is suitable for the thermal and acoustic insulation of constructions where higher temperatures and light mechanical loads (e.g. vibrations) occur. Typical examples are ovens, furnaces and exhaust ducts.

Read More

ProRox SL 980

ProRox SL 980 (ROCKWOOL HT700) is developed for the thermal and acoustic insulation of constructions where higher temperatures and/or mechanical loads (e.g. vibrations) occur

Read More

ProRox SL 540

ProRox SL 540 (ROCKWOOL 251.001) is suitable for thermal and acoustic insulation of constructions where high temperatures and light mechanical loads occur.

Read More

ProRox SL 560

ProRox SL 560 (ROCKWOOL 251) is suitable for thermal and acoustic insulation of constructions where high temperatures and mechanical loads (e.g. vibrations) occur.

Read More

ProRox SL 580

The pressure resistant slab is developed for the thermal insulation of tank roofs subjected to pedestrian traffic, and the thermal/acoustic insulation of constructions subjected to a mechanical load.

Read More

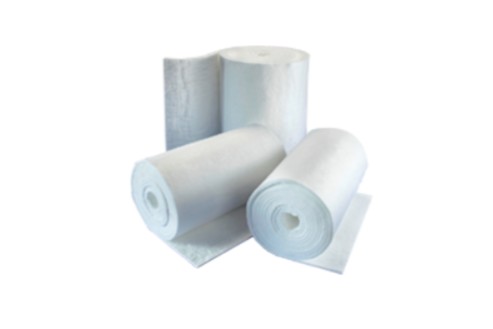

Ceramic Fiber Blankets

Ceramic fiber blanket is a kind of continuous cotton tiled fiber blanket made by pure material melted at high temperature. This is also called as Alumina-Silica Ceramic Fiber Product

Read More